Introduction

A thorough analysis of MIT and Commonwealth Fusion Systems‘ high-temperature superconducting magnets demonstrates that they satisfy the specifications needed for a small, cost-effective fusion power station.

Engineers at MIT’s Plasma Science and Fusion Centre (PSFC) attained a big milestone in the early morning hours of September 5, 2021, when a brand-new kind of magnet made of superconducting material at high temperatures achieved a record-breaking 20 tesla of magnetic field intensity for a large-scale magnet. That is the level of effort required to construct a fusion power plant, which is predicted to provide a net output of power and perhaps usher in an age of nearly endless power generation.

The test was deemed successful right away as it satisfied every requirement set forth in the design of the new fusion device, known as SPARC, for which the magnets constitute the primary enabling technology. As the exhausted group of experimenters, who had worked extremely hard to make the breakthrough possible, celebrated, champagne corks burst.

However, the process was far from over after that. In the months that followed, the team disassembled and examined each component of the magnet, examined and analysed data from hundreds of instruments that captured test details, ran two more test runs on the same magnet, and finally pushed it to its limit to discover the specifics of any potential failure modes.

The result of all of this work is a comprehensive study written by researchers at PSFC and Commonwealth Fusion Systems (CFS), a spinout firm from MIT. It was published in a special edition of IEEE Transactions on Applied Superconductivity in March, along with six other peer-reviewed studies. Together, the papers cover the process of designing and building the magnet, as well as the diagnostic tools required to assess its functionality and identify any lessons that may be gained. The researchers discovered that, all things considered, the computer modelling and forecasts were accurate, confirming that the magnet’s special design components may be the basis for a fusion power plant.

Facilitating Useful Fusion Power

Dennis Whyte, a Hitachi America Professor of Engineering who just resigned as the PSFC’s director, claims that the magnet’s successful test was “the most significant activity, in my view, in the last 30 years of fusion research.”

According to the demonstration on September 5, nearly all advanced superconducting magnets on the market have sufficient strength to possibly manufacture fusion energy, but only at prices and sizes that would never be reasonable or profitable. Then, according to Whyte, “it effectively altered the expense per watt of a fusion reactor by a factor of almost 40 in one day” when the experiments demonstrated the viability of such a powerful magnet at a significantly reduced size.

“Now, fusion has a chance,” Whyte says. Tokamaks, the most commonly used design for experimental fusion devices, “have a chance, in my view, of being economical because you’ve got a quantum modification to your capacity, with the identified incarceration physics rules, about having the capacity to greatly reduce the size and cost of objects that would make fusion possible.”

Plans for a new generation of fusion devices—the ones designed by MIT and CFS, as well as similar designs by other commercial fusion companies—are proven to be grounded in science by the extensive data and analysis from the PSFC’s magnet test, as described in the six new papers.

Superconducting Innovation

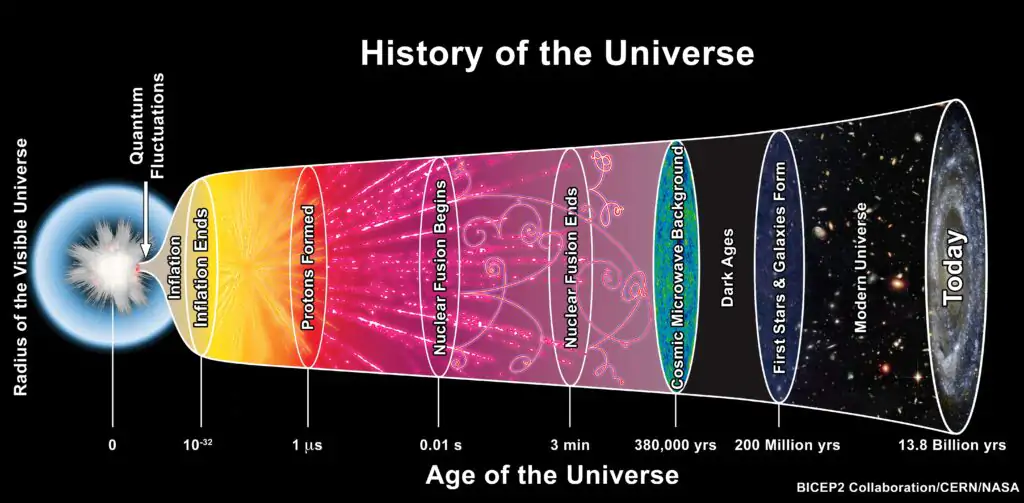

Fusion, the act of joining light atoms to generate heavier ones, drives the sun and stars; however, regulating that process on Earth has proven to be a challenging endeavour, with decades of effort and billions of dollars invested in experimental devices. The long-sought, but never realised, objective is to construct a fusion power plant that generates more energy than it uses. Such a power station may generate energy without creating greenhouse gases and with very little radioactive waste. Fusion’s fuel, a kind of hydrogen that can be extracted from seawater, is almost infinite.

However, in order for it to operate, the fuel must be compressed at extremely high temperatures and pressures. Because no known material can endure such temperatures, the fuel must be kept in place by incredibly intense magnetic fields.

To generate such powerful fields, superconducting magnets are required; however, all prior fusion magnets were created with a superconducting material that demands cold temperatures of around 4 degrees beyond absolute zero (4 kelvins, or -270 degrees Celsius). In the past few years, a newer substance known as REBCO, or rare-earth barium copper oxide, has been used in fusion magnets, enabling them to operate at 20 kelvins, a temperature that, whereas only 16 kelvins higher, provides significant advantages in terms of material properties and practical engineering.

It was not enough to simply replace the current magnet designs with this new, higher-temperature superconducting material. Rather, Whyte explains, “it was a rework of almost all the principles that you use to build superconducting magnets, starting from scratch.” “Extraordinarily different from the previous generation of superconductors” describes the new REBCO material. You’re going to innovate from the ground up, rather than merely replace and adapt. Now that patent protection has been granted, the specifics of that redesign process are described in the recently published publications in Transactions on Applied Superconductivity.

One Crucial Creation: No Insulation

The removal of insulation surrounding the narrow, flat strips of superconducting tape that made up the magnet was one of the revolutionary inventions that many people in the field doubted would succeed. Conventional superconducting magnets, like almost all electrical cables, are completely insulated to avoid short circuits between the wires. However, the engineers in the new magnet left the tape entirely exposed, relying instead on REBCO’s far higher conductivity to maintain the flow of current through the substance.

Zach Hartwig, the Robert N. Noyce Career Development Professor in the Department of Nuclear Science and Engineering, states that “when we started this project, let’s say 2018, the technology of using high-temperature superconductors to build large-scale high-field magnets was in its infancy.” Heading the engineering group of the PSFC, where he also has a co-appointment, Hartwig oversaw the magnet development project. “Small benchtop experiments were the state of the art, not really representative of what it takes to build a full-size thing.” Our magnet development endeavour began at benchtop scale and quickly reached full scale, the team says, adding that they developed a 20,000-pound magnet that generated a consistent, uniform magnetic field of little over 20 teslas, which is far more than any large-scale magnetic field that has ever been produced.

“The traditional manufacturing process for these magnets adds conductor width and insulation between the windings; it is important to monitor the voltage spikes that occur during unusual events, such as shutdown, and are more sensitive. In addition, it provides.” more room for other features, such as increased cooling or increased energy efficiency in the building.

The magnet setup is a somewhat smaller-scale copy of those that will make up the donut-shaped chamber of the SPARC fusion device, which is now being manufactured by CFS in Devens, Massachusetts. It is made up of 16 pancake-shaped plates, each with a spiral winding of superconducting tape on one side and helium gas cooling channels on the other side.

However, there was a lot riding on the test programme, and the no-insulation design was deemed dangerous. According to Hartwig, this was the first magnet produced on a large enough scale that truly investigated the process of creating, testing, and manufacturing a magnet using the so-called no-insulation, no-twist technique. “The public was taken aback when we revealed that it was a coil without insulation.”

Reaching the Edge and Beyond

Initial tests documented in previous articles showed that the design and manufacturing process not only worked but was also very robust, something that had been questioned by many scholars The following two tests in 2021 the end also pushed the machine to its limits by shutting down the intentionally highly unstable conditions it created upon the output voltage, which can cause dangerous overheating The shutdown is what very bad for handling such magnets, which can damage the machine.

The test program’s goal, according to Hartwig, was “to truly go off and intentionally calm a full-scale magnet, to ensure we can get the vital information at the appropriate size and the right conditions to improve our knowledge, verify the coding rules, and then to take the magnet separate and observe what went incorrect why did it go incorrect and how do we take the next step towards fixing that.” The test was really successful.

Hartwig claims that a plethora of fresh information was discovered during that concluding test, which resulted in the melting of one of the sixteen pancakes. One reason is that, in order to design and forecast the performance of various aspects of the magnet’s operation, they had been using a number of different computational models. Overall, these models agreed with their predictions and were well-validated by the set of experiments and empirical measurements. However, the model predictions did not agree when it came to estimating the effect of the quench, hence, experimental data was required in order to assess the models’ viability.

“The most accurate models we had anticipated nearly precisely the magnet’s heating behaviour, the extent of its heating as it began to quench, and the location of the magnet’s subsequent damage,” the author said. “That analysis basically told us exactly the physics that would be going on, and it showed us which simulations were helpful for the future and which were going to fall by the side because they’re not right,” as one of the new stories goes on to outline.

“Basically, when we examined all other elements of the coil’s performance, we did the most disastrous thing possible to the coil on purpose,” Whyte explains. And we discovered that, although one isolated region of the coil had some melting, the majority of it escaped undamaged. “Only a tiny portion of the coil’s capacity was damaged.” And it led to innovations in design that should shield the real fusion device magnets against harm of this sort, even in the worst circumstances.

Hartwig highlights that the team’s ability to complete such a radical new record-setting magnet design on time and within budget was largely made possible by the extensive knowledge, experience, and equipment gathered over decades of operation at the Francis Bitter Magnet Laboratory, the Alcator C-Mod tokamak, and other work conducted at PSFC. He states, “This gets to the core of what an institution like this is capable of.” “We had everything we needed—people, space, infrastructure, and capability—all under one roof to do these things.”

According to him, MIT and CFS’s partnership was crucial in achieving joint goals that neither organisation could have achieved alone. This was achieved by fusing the most potent elements of a commercial enterprise with an academic institution. One of CFS’s most significant contributions, for instance, was using the strength of a private company to build and accelerate a supply chain at a level and pace never seen before for the project’s most important component: 300 kilometres (186 miles) of high-temperature superconductor. This material was acquired with strict quality control in less than a year and installed into the magnet on schedule.

According to him, another key factor in the achievement was the merging of the two teams—MIT and CFS. The fact that we viewed ourselves as cohesive allowed us to do what we achieved.

Conclusion

A significant step forward in the search for fusion energy is the development of superheated magnets by Commonwealth Fusion Systems and MIT. The cost-effectiveness of tiny fusion electric devices is getting closer thanks to the successful testing of these magnets. The obstacles facing fusion research have mostly been addressed by collaborations between academics and business, opening the door to a more sustainable and clean energy future.

FAQ's

Q: What is fusion energy?

A: Fusion energy is produced with the help of the joining of light atoms to make heavier ones; that is the same mechanism that drives stars and the solar system. It offers an almost endless supply of clean strength with negligible environmental effects.

Q: Why are superconducting magnets crucial for fusion research?

A: Superconducting magnets are vital for confining the extraordinarily warm plasma required for fusion reactions. They generate intense magnetic fields to comprise the plasma, making an allowance for managed fusion reactions to arise.

Q: What makes MIT and Commonwealth Fusion Systems’ magnet breakthrough significant?

A: The improvement of excessive-temperature superconducting magnets at MIT’s Plasma Science and Fusion Centre (PSFC) demonstrates the feasibility of price-powerful fusion electricity stations. This step forward could doubtlessly revolutionise the electricity industry by imparting a sustainable alternative to fossil fuels.

Q: How does the collaboration between MIT and Commonwealth Fusion Systems contribute to this achievement?

A: The partnership between academia and industry has increased the development and testing of fusion technology. Commonwealth Fusion Systems’ information in commercialization and supply chain management, blended with MIT’s research skills, has brought about rapid development in fusion studies.